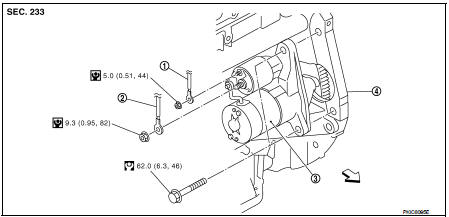

Nissan Juke Service and Repair Manual : MR16DDT : Exploded View

REMOVAL

1. “S” terminal harness

2. “B” terminal harness

3. Starter motor

4. Cylinder block

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

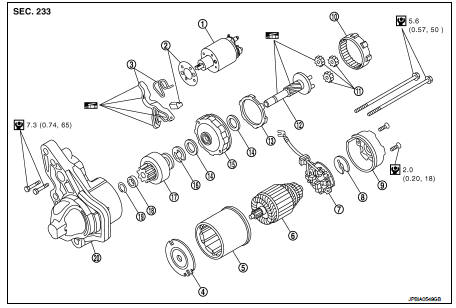

DISASSEMBLY

Type: S114-902

1. Magnetic switch assembly

2. Dust cover kit

3. Shift lever set

4. Center bracket (A)

5. Yoke assembly

6. Armature assembly

7. Brush holder assembly

8. Thrust washer

9. Rear cover assembly

10. Internal gear

11. Planetary gear

12. Pinion shaft

13. Packing

14. Thrust washer

15. Center bracket (P)

16. E-ring

17. Pinion assembly

18. Pinion stopper

19. Pinion stopper clip

20. Gear case assembly

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: High-temperature grease point

: High-temperature grease point

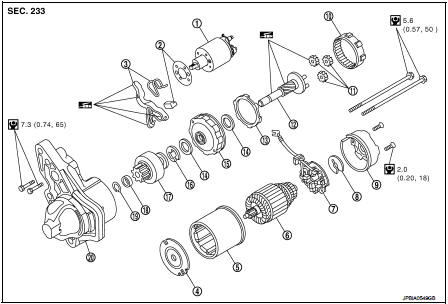

Type: S114-955

1. Magnetic switch assembly

2. Dust cover kit

3. Shift lever set

4. Center bracket (A)

5. Yoke assembly

6. Armature assembly

7. Brush holder assembly

8. Thrust washer

9. Rear cover assembly

10. Internal gear

11. Planetary gear

12. Pinion shaft

13. Packing

14. Thrust washer

15. Center bracket (P)

16. E-ring

17. Pinion assembly

18. Pinion stopper

19. Pinion stopper clip

20. Gear case assembly

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: High-temperature grease point

: High-temperature grease point

NOTE

:

Apply high-temperature grease to lubricate the bearing, gears and frictional

surface when assembling the

starter.

HR16DE : Inspection and Adjust

HR16DE : Inspection and Adjust

INSPECTION

Magnetic Switch Check

• Before starting to check, disconnect the battery cable from the negative

terminal.

• Disconnect “M” terminal of starter motor.

1. Continuity test [between “S ...

MR16DDT : Removal and Installation

MR16DDT : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124,

"Removal and Installation".

2. Drain engine coolant from radiator. Refer to CO-11, "Draining&quo ...

Other materials:

Repair and replacement procedure

The front air bags, side air bags, curtain air bags and pretensioners are designed

to activate on a one-time-only basis. As a reminder, unless it is damaged, the supplemental

air bag warning light will remain illuminated after inflation has occurred.

Repair and replacement of these systems shou ...

P0705 transmission range switch A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, p ...

Measurement of weights

Secure loose items to prevent weight shifts that could affect the balance of

your vehicle. When the vehicle is loaded, drive to a scale and weigh the front and

the rear wheels separately to determine axle loads.

Individual axle loads should not exceed either of the Gross Axle Weight Ratings

( ...