Nissan Juke Service and Repair Manual : Lower link

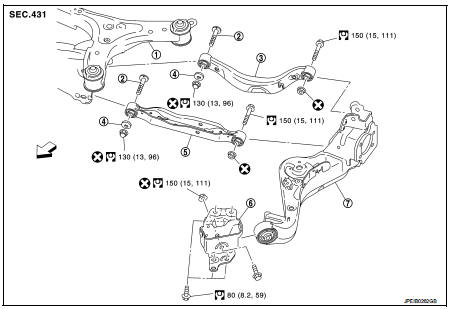

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove tires. Refer to WT-7, "Removal and Installation".

2. Set jack under suspension arm.

CAUTION:

• Never damage the suspension arm with a jack.

• Check the stable condition when using a jack

.

3. Remove stabilizer link. Refer to RSU-34, "Removal and Installation".

4. Remove eccentric disc, adjusting bolt, mounting bolt, and nut, then remove lower link.

5. Perform inspection after removal. Refer to RSU-31, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Perform final tightening of rear suspension member and axle installation position (rubber bushing), under unladen conditions with tires on level ground.

• Never reuse lower link mounting nut.

• Perform inspection after installation. Refer to RSU-31, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check lower link and bushing for any deformation, cracks, or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel alignment. Refer to RSU-20, "Inspection".

2. Adjust neutral position of steering angle sensor. Refer to BRC-149, "Work Procedure" (With ESP).

Suspension arm

Suspension arm

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Upper link

Upper link

Exploded View

1. Rear suspension member

2. Adjusting bolt

3. Upper link

4. Eccentric disk

5. Lower link

6. Suspension arm bracket

7. Suspension arm

: Vehicle front

: Always replace afte ...

Other materials:

P0850 PNP switch

Description

When the selector lever position is P or N (CVT), Neutral position (M/T),

park/neutral position (PNP) signal is

ON.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III?

YES >> GO TO 2.

NO >& ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

For frontal collision : When SRS is not activated in a collision

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below

apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensure that all vehicle body

and structural repairs have been

completed.

2. Check the SRS components using the t ...