Nissan Juke Service and Repair Manual : Intake manifold

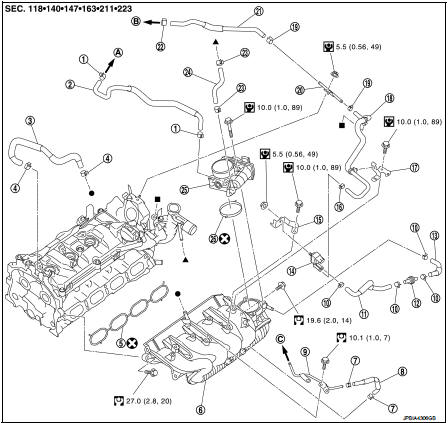

Exploded View

1. Clamp

2. Water hose

3. PCV hose

4. Clamp

5. Gasket

6. Intake manifold

7. Clamp

8. Vacuum hose

9. Vacuum gallery assembly

10. Clamp

11. EVAP hose

12. EVAP service port valve

13. EVAP hose

14.EVAP canister purge volume control

solenoid valve

15. Bracket

16. Clamp

17. Bracket

18. EVAP hose

19. Clamp

20. EVAP tube

21. EVAP hose

22. Clamp

23. Clamp

24. Water hose

25. Electric throttle control actuator

26. Gasket

A. To turbocharger B. To centralized under-floor piping C. To recirculation valve hose

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly

Removal and Installation

REMOVAL

1. Remove engine cover. Refer to EM-25, "Exploded View".

2. Pull out oil level gauge.

CAUTION:

Cover the oil level gauge guide openings to avoid entry of foreign materials.

3. Disconnect turbocharger boost sensor (with intake air temperature sensor 2) harness connector. Refer to EM-31, "Exploded View".

4. Remove air inlet tube assembly. Refer to EM-31, "Exploded View".

5. Disconnect water hoses from electric throttle control actuator as follows: • Attach plug to prevent engine coolant leakage when engine coolant is not drained. Refer to CO-11, "Draining".

CAUTION:

Perform this step when the engine is cold.

NOTE:

This step is not required when removing only intake manifold.

6. Disconnect electric throttle control actuator harness connector.

7. Remove electric throttle control actuator.

CAUTION

:

• Handle carefully to avoid any shock to electric throttle control

actuator.

• Never disassemble electric throttle control actuator.

8. Disconnect EVAP canister purge volume control solenoid valve harness connector, and them remove bracket with EVAP canister purge volume control solenoid valve.

9. Remove vacuum gallery.

10. Disconnect PCV hose (intake manifold side).

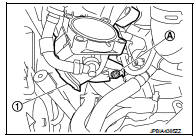

11. Remove intake manifold (1) with the following procedure.

• Loosen and remove intake manifold mounting bolt (A).

• Loosen mounting bolts in reverse order as shown in the figure.

: Engine front

: Engine front

NOTE:

Disregard the numerical order No.6 in removal.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

INSTALLATION

Note the following, and install in the reverse order of removal.

Intake Manifold

1. Check if gasket is not dropped from the installation groove of intake

manifold.

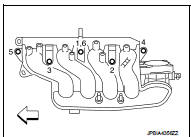

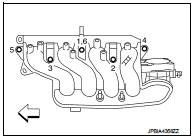

2. Install intake manifold with the following procedure:

a. Tighten in numerical order as shown in the figure.

: Engine front

: Engine front

NOTE:

• Tighten bolt the No.1 in two steps.

• The numerical order No.6 shows the second step.

3. Install in the reverse order of removal after this step.

Electric Throttle Control Actuator • Tighten bolts of electric throttle control actuator equally and diagonally in several steps.

• Perform “Throttle Valve Closed Position Learning” after repair when removing harness connector of the electric throttle control actuator. Refer to EC-135, "Work Procedure".

• Perform “Throttle Valve Closed Position Learning” and “Idle Air Volume Learning” after repair when replacing electric throttle control actuator. Refer to EC-135, "Work Procedure" and EC-136, "Work Procedure".

Air cleaner and air duct

Air cleaner and air duct

Exploded View

1. Mass air flow sensor

2. Gasket

3. Clamp

4. Air duct (suction side)

5. Clamp

6. Air cleaner cover assembly

7. Mounting rubber

8. Air cleaner filter

9. Air cleaner body ...

Charge air cooler

Charge air cooler

Exploded View

1. Air inlet tube assembly

2. Air inlet tube bracket

3. Clamp

4. Air inlet hose

5. Gasket

6. Turbocharger

7. Mounting rubber

8. Charge air cooler

9. Air inlet tube assem ...

Other materials:

Engine maintenance (K9K)

Drive belt

DRIVE BELT : Checking Drive Belts

WARNING:

Be sure to perform when the engine is stopped.

1. Inspect belts for cracks, fraying, wear and oil. If necessary,

replace.

2. Evaluate manually if the belt is enough tensioned (tension cannot

be measured by way of frequency meter).

CAU ...

B2628 outside antenna

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Disconnect outside key antenna (rear bumper) connector.

2. Perform “INTELLIGENT KEY” Self Diagnostic Result.

Is outside key antenna DTC detected?

YES >> Refer to DLK-65, "Diagnosis ...

U1010 control unit (can)

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...