Nissan Juke Service and Repair Manual : HR16DE : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124, "Removal and Installation".

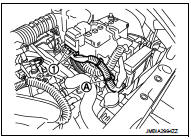

2. Remove radiator reservoir tank. Refer to CO-17, "Exploded View".

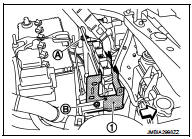

3. Disconnect harness connectors (1) from battery terminal with fusible link.

4. Remove harness fixing clips (A) from F/L·fuse holder bracket.

5. Remove harness fixing clips (A) from F/L·fuse holder bracket.

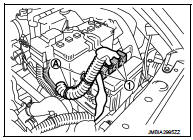

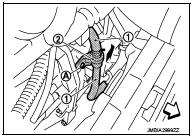

6. Disconnect harness connector (1) from ECM.

7. Disengage pawl using a flat-bladed screwdriver (A). Remove F/ L·fuse holder.

: Vehicle front

: Vehicle front

8. Move F/L·fuse holder and harness to a location where they do not inhibit work.

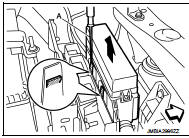

9. Remove harness fixing clips (A) from F/L·fuse holder bracket.

10. Remove mounting bolt (A) and nut (B) of F/L·fuse holder bracket (1), and then remove F/L·fuse holder bracket.

: Vehicle front

: Vehicle front

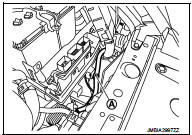

11. Remove mounting bolt (A), and then move water hose (1) and heater thermostat (2) to a location where they do not inhibit work (CVT models).

: Vehicle front

: Vehicle front

12. Remove “B” terminal nut and “B” terminal harness.

13. Remove “S” terminal nut and “S” terminal harness.

14. Remove starter motor mounting bolts.

15. Remove starter motor towards vehicle upper.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Be careful to tighten “B” terminal nut to the specified torque.

HR16DE : Exploded View

HR16DE : Exploded View

REMOVAL

1. Cylinder block

2. “B” terminal harness

3. “S” terminal harness

4. Starter motor

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

DISASSEMBLY

Type: M000T32172ZE

1. “M” ...

HR16DE : Inspection and Adjust

HR16DE : Inspection and Adjust

INSPECTION

Magnetic Switch Check

• Before starting to check, disconnect the battery cable from the negative

terminal.

• Disconnect “M” terminal of starter motor.

1. Continuity test [between “S ...

Other materials:

Headlight switch

Lighting

1 Turn the switch to the position:

The front parking, side marker, tail, license plate, instrument lights and daytime

running lights (for NISMO models) will come on.

2 Turn the switch to the position:

Headlights will come on and all the other lights remain on. However, the daytime ...

Combination switch input circuit

Diagnosis Procedure

1.CHECK INPUT 1 - 5 CIRCUIT FOR OPEN

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check continuity between BCM harness connector and combination switch harness

connector.

Does continuity exist?

YES >> GO TO 2.

NO >> ...

Thermostat

Exploded View

1. Radiator hose (upper)

2. Water inlet

3. Rubber ring

4. Thermostat

A. To radiator

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-37, "Draining".

CAUTION:

P ...