Nissan Juke Service and Repair Manual : Hoses

HOSE REMOVAL AND INSTALLATION

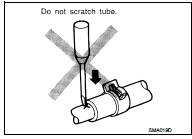

• To prevent damage to rubber hose, do not pry off rubber hose with tapered tool or screwdriver.

• To reinstall the rubber hose securely, check that hose insertion length and orientation is correct. (If tube is equipped with hose stopper, insert rubber hose into tube until it butts up against hose stopper.)

HOSE CLAMPING

• If old rubber hose is re-used, install hose clamp in its original position (at the indentation where the old clamp was). If there is a trace of tube bulging left on the old rubber hose, align rubber hose at that position.

• Discard old clamps; replace with new ones.

• After installing plate clamps, apply force to them in the direction of the arrow, tightening rubber hose equally all around.

Turbocharger (If Equipped)

Turbocharger (If Equipped)

The turbocharger turbine revolves at extremely high speeds and

becomes very hot. Therefore, it is essential to maintain a clean supply

of oil flowing through the turbocharger and to follow all requi ...

Engine Oils

Engine Oils

Prolonged and repeated contact with used engine oil may cause skin cancer.

Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as s ...

Other materials:

Windshield glass

Exploded View

1. Windshield glass molding

2. Dam rubber (upper)

3. Upper clip

4. Windshield glass

5. Dam rubber (lower)

6. Lower clip

7. Mirror base

8. Rain sensor bracket

9. Adhesive

10. Roof panel

11. Headlining assembly

12. Primer

13. Cowl top cover

14. Cowl top panel

1 ...

Electric controlled coupling oil seal

Exploded View

1. Rear final drive assembly

2. Electric controlled coupling oil seal

A. Oil seal lip

: Vehicle front

: Always replace after every

disassembly.

: Apply multi purpose grease

: Apply gear oil.

Removal and Installation

REMOVAL

1. Remove rear drive shafts. Refer to RAX-17, & ...

Tow Truck Towing

CAUTION:

• All applicable state or Provincial laws and local laws regarding the towing

operation must be

obeyed.

• It is necessary to use proper towing equipment to avoid possible damage to the

vehicle during towing

operation. Towing is in accordance with Towing Procedure Manual at dealer.

...