Nissan Juke Service and Repair Manual : Horn function

Component Function Check

1.CHECK FUNCTION 1

1. Disconnect vehicle security horn relay.

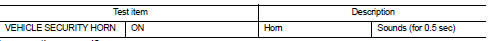

2. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

3. Check the horn operation.

Is the operation normal? YES >> GO TO 2.

NO >> Go to SEC-225, "Diagnosis Procedure".

2.CHECK FUNCTION 2

1. Reconnect vehicle security horn relay.

2. Disconnect horn relay.

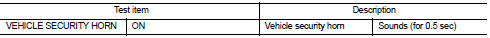

3. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM” using CONSULT- III.

4. Check the horn operation.

Is the operation normal? YES >> INSPECTION END

NO >> Go to SEC-225, "Diagnosis Procedure".

Diagnosis Procedure

1.INSPECTION START

Perform inspection in accordance with procedure that confirms malfunction.

Which procedure confirms malfunction? Component Function Check 1>>GO TO 2.

Component Function Check 2>>GO TO 4.

2.CHECK HORN FUNCTION

Check that horn functions properly using horn switch.

Do horns sound? YES >> GO TO 3.

NO >> Check horn circuit. Refer to HRN-3, "Wiring Diagram".

3.CHECK HORN CONTROL CIRCUIT

1. Disconnect horn relay.

2. Disconnect IPDM E/R connector.

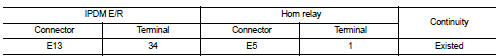

3. Check continuity between IPDM E/R harness connector and horn relay harness connector.

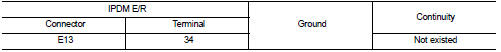

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

4.CHECK HORN FUNCTION

Check that vehicle security horn functions properly using horn switch.

Do horns sound? YES >> GO TO 5.

NO >> Check vehicle security horn circuit. Refer to HRN-3, "Wiring Diagram".

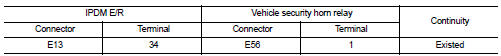

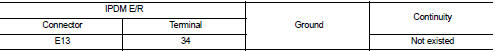

5.CHECK VEHICLE SECURITY HORN CONTROL CIRCUIT

1. Disconnect IPDM E/R connector.

2. Check continuity between IPDM E/R harness connector and vehicle security horn relay harness connector.

3. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Hood switch

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indicati ...

Security indicator lamp

Security indicator lamp

Component Function Check

1.CHECK FUNCTION

1. Perform “THEFT IND” in the “ACTIVE TEST” mode of “BCM” using

CONSULT-III.

2. Check security indicator lamp operation.

Is the inspection result norm ...

Other materials:

Unlock sensor

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “UNLK SEN -DR” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Unlock sensor ...

Brake pedal vibration or operation sound occurs

Description

• Brake pedal vibrates and motor sound from ABS actuator and electric unit

(control unit) occurs, when the

engine starts.

• Brake pedal vibrates during braking.

CAUTION:

Vibration may be felt during brake pedal is lightly depressed (just placing a

foot on it) in the following

...

Handling for Adhesive and Primer

• Never use an adhesive that is past its usable date. Shelf life of this

product is limited to six months after the

date of manufacture. Carefully adhere to the expiration or manufacture date

printed on the box.

• Keep primers and adhesive in a cool, dry place. Ideally, they should be stored

...