Nissan Juke Service and Repair Manual : Hazard switch

Component Function Check

1.CHECK HAZARD SWITCH SIGNAL BY CONSULT-III

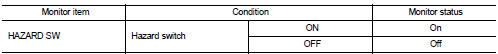

CONSULT-III DATA MONITOR

CONSULT-III DATA MONITOR

1. Turn the ignition switch ON.

2. Select “HAZARD SW” of BCM (FLASHER) data monitor item.

3. With operating the hazard switch, check the monitor status.

Is the inspection result normal? YES >> Hazard switch circuit is normal.

NO >> Refer to EXL-72, "Diagnosis Procedure".

Diagnosis Procedure

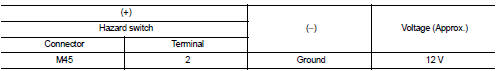

1.CHECK HAZARD SWITCH SIGNAL INPUT

1. Turn ignition switch OFF.

2. Disconnect hazard switch connector.

3. Check voltage between hazard switch connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

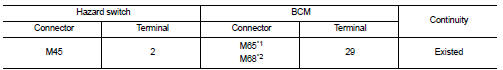

2.CHECK HAZARD SWITCH SIGNAL OPEN CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between hazard switch harness connector and BCM harness connector.

*1: Without Intelligent Key *2: With Intelligent Key

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

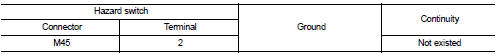

3.CHECK HAZARD SWITCH SIGNAL SHORT CIRCUIT

Check continuity between hazard switch harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-93, "Removal and Installation" (with Intelligent Key) or BCS-161, "Removal and Installation" (without Intelligent Key).

NO >> Repair or replace harness.

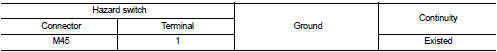

4.CHECK HAZARD SWITCH GROUND OPEN CIRCUIT

Check continuity between hazard switch harness connector and ground.

Is the inspection result normal? YES >> Replace hazard switch.

NO >> Repair or replace harness.

Turn signal lamp circuit

Turn signal lamp circuit

Component Function Check

1.CHECK TURN SIGNAL LAMP

CONSULT-III ACTIVE TEST

1. Select “FLASHER” of BCM (FLASHER) active test item.

2. With operating the test items, check that the turn signal lamps ...

Other materials:

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

B2205 vehicle speed

Description

Vehicle speed signal is transmitted from ABS actuator and electric unit

(control unit) via CAN communication

to combination meter.

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS OF ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform “Self Diagnost ...

Symptom diagnosis

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom Table

1. Perform “Data Monitor” of CONSULT-III to check for any malfunctioning

item.

2. Check the malfunction combinations.

3. Identify the malfunctioning part from the agreed combination and repair or

replace the part.

...