Nissan Juke Service and Repair Manual : Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited? YES >> GO TO 2.

NO >> Go to EC-778, "Diagnosis Procedure".

2.CHECK FUEL INJECTOR FUNCTION

With CONSULT-III

With CONSULT-III

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT-III.

3. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-III

Without CONSULT-III

1. Let engine idle.

2. Listen to each fuel injector operating sound.

Clicking noise should be heard.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-778, "Diagnosis Procedure".

Diagnosis Procedure

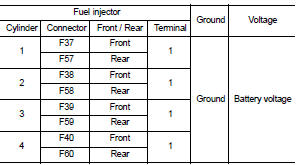

1.CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect fuel injector harness connector.

3. Turn ignition switch ON.

4. Check the voltage between fuel injector harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1

• IPDM E/R connector E15

• 15 A fuse (No. 62)

• Harness for open or short between fuel injector and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

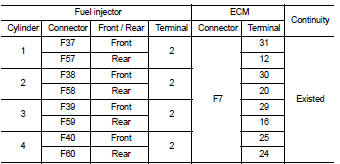

3.CHECK FUEL INJECTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between fuel injector harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL INJECTOR

Refer to EC-779, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace malfunctioning fuel injector.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness or connectors.

Component Inspection

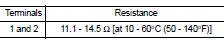

1.CHECK FUEL INJECTOR

1. Turn ignition switch OFF.

2. Disconnect fuel injector harness connector.

3. Check resistance between fuel injector terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning fuel injector.

Electrical load signal

Electrical load signal

Description

The electrical load signal (Headlamp switch signal, rear window defogger

switch signal, etc.) is transferred to

ECM through the CAN communication line.

Component Function Check

1.CHE ...

Fuel pump

Fuel pump

Component Function Check

1.CHECK FUEL PUMP FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose with two fingers.

Fuel pressure pulsation should be felt on the fuel feed

hose for 1 second ...

Other materials:

Thermo control amplifier

Component Function Check

1.CHECK A/C ON SIGNAL

With CONSULT-III

1. Turn ignition switch ON.

2. Select “AIR CONDITIONER” of “BCM” using CONSULT-III.

3. Select “THERMO AMP” in “DATA MONITOR” mode, and check status under the

following condition.

Is the inspection result normal?

YES >> ...

Cylinder head

Exploded View

REMOVAL

1. Cylinder head assembly

2. Cylinder head bolt

3. Washer

4. Cylinder head gasket

A.Tightening must be done following the installation procedure.

Refer to EM-209

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: Should be lubricated with oil.

D ...

ESP warning lamp

Component Function Check

1.CHECK ESP WARNING LAMP FUNCTION

Check that ESP warning lamp in combination meter turns ON for approx. 1

second after ignition switch is

turned ON.

CAUTION:

Never start engine.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to d ...