Nissan Juke Service and Repair Manual : Front fender

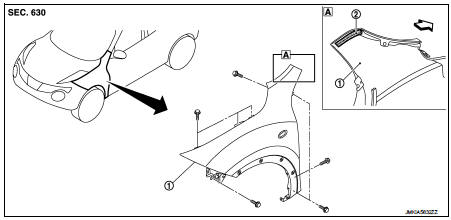

Exploded View

1. Front fender assembly 2. Front fender stiffener

: Vehicle fr

: Vehicle fr

Removal and Installation

REMOVAL

1. Remove front fillet molding. Refer to EXT-26, "FRONT FILLET MOLDING : Removal and Installation".

2. Remove front bumper fascia assembly. Refer to EXT-13, "Removal and Installation".

3. Remove sill cover. Refer to EXT-23, "Removal and Installation".

4. Remove fender protector. Refer to EXT-22, "Removal and Installation".

5. Remove front fender cover. Refer to EXT-20, "Exploded View".

6. Remove front combination lamp. Refer to EXL-91, "Removal and Installation".

7. Remove side turn signal lamp. Refer to EXL-98, "Removal and Installation".

8. Remove mounting bolts of front fender assembly.

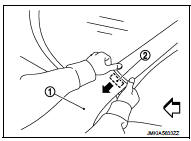

9. Remove front fender stiffener (2) from the vehicle body while carefully pulling upper portion of front fender (1) toward vehicle outside.

: Vehicle front

: Vehicle front

10. Remove front fender assembly.

CAUTION

:

An viscous urethane foam is installed on the back surface of front fender.

When removing the

front fender, be careful to not deform the front fender while performing the

procedure and removing

the viscous urethane foam a little at a time.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

• After installation, apply the touch-up paint (the body color) onto the head of

front fender mounting

bolts.

• After installation, adjust the following part.

- Hood assembly: Refer to DLK-305, "HOOD ASSEMBLY : Adjustment".

- Front door: Refer to DLK-319, "DOOR ASSEMBLY : Adjustment".

Radiator core support

Radiator core support

HR16DE

HR16DE : Exploded View

1. Radiator core support upper

2. Air guide RH (MT models)

3. Radiator core support lower

4. Air guide LH 5. Air guide (upper)

6. Air guide LH (CVT models)

7. ...

Front door

Front door

Exploded View

1. Front door panel

2. Grommet

3. TORX bolt

4. Door striker

5. Door pad

6. Bumper rubber

7. Door check link

8. Door hinge (lower)

9. Door hinge (upper)

10. Grommet

: D ...

Other materials:

U1001 Can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each c ...

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW THE CUSTOMER FOR THE SYMPTOM

Interview the customer for the symptom (the condition and the environment

when the incident/malfunction

occurs).

>> GO TO 2.

2.CHECK SYMPTOM

Check the symptom from ...

B210C starter control relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B210C is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

PCS-30, "DTC Logic".

• When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1

second), the DTC B210C may be

detected.

DTC ...