Nissan Juke Service and Repair Manual : Door switch

Component Function Check

1.CHECK FUNCTION

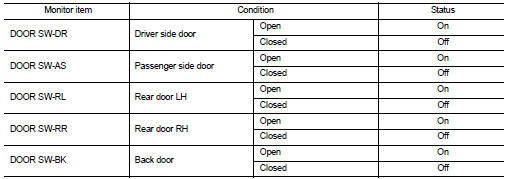

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR SW-DR”, “DOOR SW-AS”, “DOOR SW-RL”, “DOOR SW-RR”, “DOOR SW-BK” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Door switch is OK.

NO >> Refer to DLK-258, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK DOOR SWITCH INPUT SIGNAL

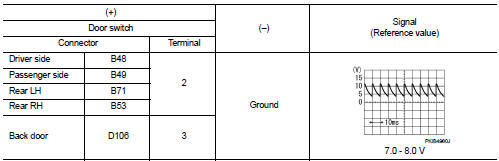

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check signal between malfunctioning door switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES-1 >> Back door: GO TO 3.

YES-2 >> Other door: GO TO 4.

NO >> GO TO 2.

2.CHECK DOOR SWITCH CIRCUIT

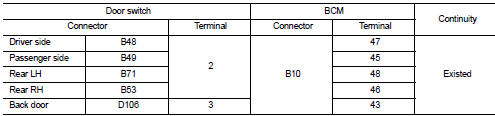

1. Disconnect BCM connector.

2. Check continuity between door switch harness connector and BCM harness connector.

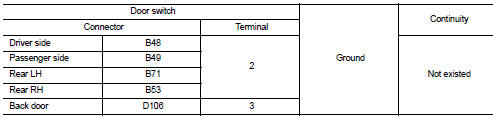

3. Check continuity between door switch harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

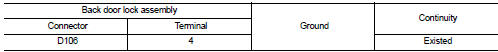

3.CHECK BACK DOOR SWITCH CIRCUIT

Check continuity between back door lock assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK DOOR SWITCH

Refer to DLK-259, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace malfunctioning door switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

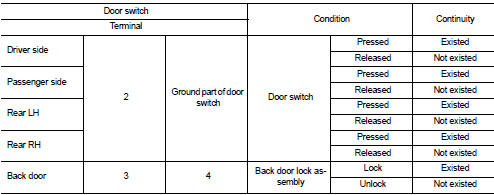

1.CHECK DOOR SWITCH

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check continuity between door switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunction door switch.

Door request switch

Door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-DR”, “REQ SW-AS” in “DATA MONITOR” mode.

3. Check that the function operates nor ...

Hazard function

Hazard function

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “FLASHER” in “ACTIVE TEST” mode.

3. Check that the function operates normally according ...

Other materials:

Ignition coil, spark plug and rocker cover

Exploded View

1. Rocker cover protector

2. O-ring

3. PCV control valve

4. PCV hose

5. Clamp

6. Rocker cover gasket

7. Rocker cover

8. Clamp

9. PCV hose

10. Oil filler cap

11. Spark plug

12. Ignition coil

A. To air duct assembly

B.Tightening must be done following

the instal ...

B1212, B1213, B1214 satellite sensor RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Fuel pressure

Work Procedure

FUEL PRESSURE RELEASE

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode of “ENGINE” using

CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition s ...