Nissan Juke Service and Repair Manual : Differential side oil seal

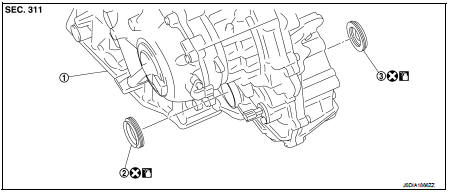

Exploded View

1. Transaxle assembly

1. Transaxle assembly

2. Differential side oil seal (left side)

3. Differential side oil seal (right side)

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: Genuine NISSAN CVT Fluid NS-2

: Genuine NISSAN CVT Fluid NS-2

Removal and Installation

REMOVAL

NOTE

:

Cap or plug openings to prevent fluid from spilling.

1. Remove the left and right front drive shafts. Refer to FAX-53, "Removal and Installation".

2. Use oil seal remover or a similar means and remove the differential side oil seal.

CAUTION:

When removing the differential side oil seal, be careful not to scratch the oil

seal mounting surfaces

of the transaxle case and converter housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse differential side oil seal.

• Apply Genuine NISSAN CVT Fluid NS-2 to the differential side oil seal lip and around the oil seal.

• When inserting the drive shaft, be sure to use a protector (SST: KV38107900). Refer to FAX-53, "Removal and Installation".

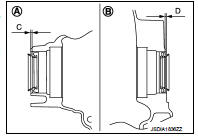

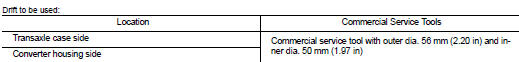

Use a drift (commercial service tool) and drive the differential side oil seal in until the amount of oil seal projection from the case edge matches dimensions (C) and (D).

CAUTION:

Be careful not to scratch the lip of the differential side oil seal

when press-fitting it.

A : Differential side oil seal (left side) B : Differential side oil seal (right side)

Dimension “C” :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

Dimension “D” :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

NOTE

:

The reference is the pull-in direction of the differential side oil seal.

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-480, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-379, "Adjustment".

Output speed sensor

Output speed sensor

Exploded View

1. Transaxle assembly

2. Output speed sensor

3. O-ring

: Vehicle front

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal ...

Water hose

Water hose

Exploded View

1. Hose clamp

2. Water hose A

3. Water hose B

4. Water hose B

5. Water bypass pipe

6. Hose clamp

7. Heater hose

8. Water hose C

A. Water outlet

B. Heater thermostat

C ...

Other materials:

B1113, B1114 satellite sensor RH

DTC Logic

DTC DETECTION LOGIC

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-12, "On ...

P0848 transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, the ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With ...

S mode switch

Component Function Check

1.CHECK S MODE INDICATOR FUNCTION

Check S mode indicator turns ON for approx. 2 seconds when ignition switch

turns ON.

Is the inspection results normal?

YES >> GO TO 2.

NO >> Go to TM-469, "Diagnosis Procedure".

2.CHECK S MODE SWITCH FUNCT ...