Nissan Juke Service and Repair Manual : Diagnosis and repair workflow

Gasoline engine models

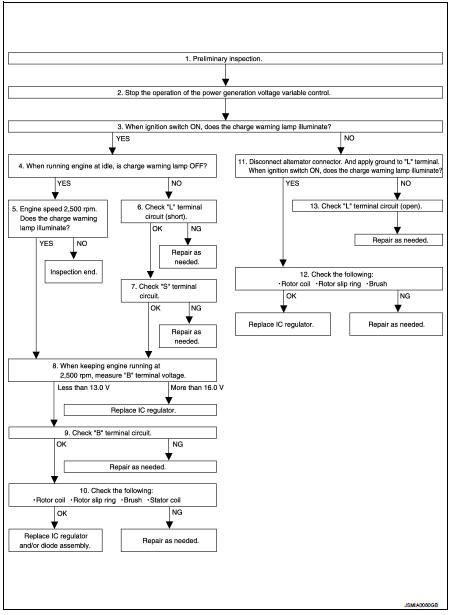

GASOLINE ENGINE MODELS : Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-17, "Inspection Procedure".

Models with battery current sensor>>GO TO 2.

Models without battery current sensor>>GO TO 3.

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures.

• After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-III, set the DUTY value of “ALTERNATOR DUTY” to 0 % by selecting “ALTERNATOR DUTY” of “Active Test”. Continue “Active Test” until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the alternator.) • Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic results history of the engine using CONSULT-III.] >> GO TO 3.

3.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 4.

NO >> GO TO 11.

4.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 5.

NO >> GO TO 6.

5.INSPECTION WITH CHARGE WARNING LAMP

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate? YES >> GO TO 8.

NO >> INSPECTION END

6.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-23, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair as needed.

7.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-24, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair as needed.

8.MEASURE “B” TERMINAL VOLTAGE

Start engine. When keeping engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show? Less than 13.0 V>>GO TO 9.

More than 16.0 V>>Replace IC voltage regulator.

9.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-20, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 10.

NO >> Repair as needed.

10.DISASSEMBLE AND CHECK ALTERNATOR

Check the following conditions.

• Rotor coil

• Rotor slip ring

• Brush

• Stator coil

Refer to CHG-29, "HR16DE : Inspection" (HR16DE), CHG-33, "MR16DDT : Inspection" (MR16DDT).

Are these normal? YES >> Replace IC voltage regulator and/or diode assembly.

NO >> Repair as needed.

11.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

1. Disconnect alternator connector and ground “L” harness side.

2. Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 12.

NO >> GO TO 13.

12.DISASSEMBLE AND CHECK ALTERNATOR

Check the following conditions.

• Rotor coil

• Rotor slip ring

• Brush

Refer to CHG-29, "HR16DE : Inspection" (HR16DE), CHG-33, "MR16DDT : Inspection" (MR16DDT).

Are these normal? YES >> Replace IC voltage regulator.

NO >> Repair as needed.

13.CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (open). Refer to CHG-21, "Diagnosis Procedure".

>> Repair as needed.

Diesel engine models

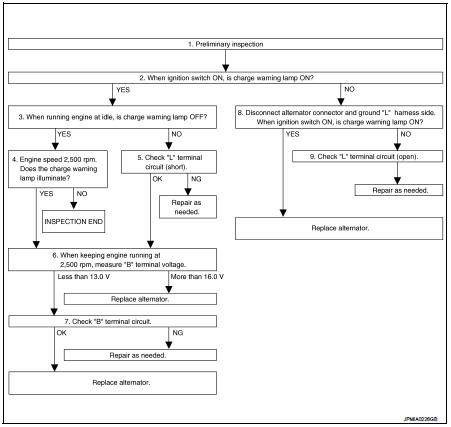

DIESEL ENGINE MODELS : Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-17, "Inspection Procedure".

>> GO TO 2.

2.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 3.

NO >> GO TO 8.

3.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 4.

NO >> GO TO 5.

4.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate? YES >> GO TO 6.

NO >> INSPECTION END

5.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-23, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair as needed.

6.MEASURE “B” TERMINAL VOLTAGE

Engine start. When keeping engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show? Less than 13.0 V>>GO TO 7.

More than 16.0 V>>Replace alternator.

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-20, "Diagnosis Procedure".

Is the inspection result normal? YES >> Replace alternator.

NO >> Repair as needed.

8.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

1. Disconnect alternator connector and ground “L” harness side.

2. Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> Replace alternator.

NO >> GO TO 9.

9.CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (open). Refer to CHG-21, "Diagnosis Procedure".

>> Repair as needed.

Basic inspection

Basic inspection

...

Charging system preliminary inspection

Charging system preliminary inspection

Inspection Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair battery ter ...

Other materials:

System

EPS system : System Description

• EPS control unit performs an arithmetical operation on data, such

as steering wheel turning force (sensor signal) from the torque

sensor, vehicle speed signal, etc. Then it generates an optimum

assist torque signal to the EPS motor according to the driving condi ...

Blower fan resistor

Exploded View

1. Heater unit assembly

2. Fan control amp.*1

3. Blower fan resistor*2

4. Blower motor

5. Blower motor cover

• *1: Automatic air conditioner

• *2: Manual air conditioner or Manual heater

Removal and Installation

REMOVAL

1. Remove instrument panel assembly. Refer to IP-13 ...

P1217 engine over temperature

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P1217 is displayed with DTC U1001, first perform the trouble diagnosis

for DTC U1001. Refer

to EC-569, "DTC Logic".

• If DTC P1217 is displayed with DTC P0607, first perform the trouble diagnosis

for DTC P0607. Refer

to EC-685, "D ...