Nissan Juke Service and Repair Manual : Diagnosis and repair work flow

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an interview utilizing DLN-37, "Diagnostic Work Sheet" and reproduce symptoms as well as fully understand it. Ask customer about his/her complaints carefully. Check symptoms by driving vehicle with customer, if necessary.

CAUTION:

Customers are not professional. Never guess easily like “maybe the customer

means that...,” or

“maybe the customer mentions this symptom

”.

>> GO TO 2.

2.CHECK SYMPTOM

Reproduce the symptom that is indicated by the customer, based on the information from the customer obtained by interview. Also check that the symptom is not caused by protection function. Refer to DLN-32, "Protection Function".

CAUTION:

When the symptom is caused by normal operation, fully inspect each portion and

obtain the understanding

of customer that the symptom is not caused by a malfunction.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

With CONSULT-III

With CONSULT-III

Perform self-diagnosis for “ALL MODE AWD/4WD”.

Is any DTC detected? YES >> Record or print self-diagnosis results. GO TO 4.

NO >> GO TO 6.

4.RECHECK SYMPTOM

With CONSULT-III

With CONSULT-III

1. Erase self-diagnostic results for “ALL MODE AWD/4WD”.

2. Perform DTC confirmation procedures for the error detected system.

NOTE

:

If some DTCs are detected at the same time, determine the order for performing

the diagnosis based on DLN-

33, "DTC Inspection Priority Chart".

Is any DTC detected? YES >> GO TO 5.

NO >> Check harness and connectors based on the information obtained by interview. Refer to GI-42, "Intermittent Incident".

5.REPAIR OR REPLACE ERROR-DETECTED PARTS

• Repair or replace error-detected parts.

• Reconnect part or connector after repairing or replacing.

• When DTC is detected, erase self-diagnostic results for “ALL MODE AWD/4WD”.

>> GO TO 7.

6.IDENTIFY ERROR-DETECTED SYSTEM BY SYMPTOM DIAGNOSIS

Estimate error-detected system based on symptom diagnosis and perform inspection.

Can the error-detected system be identified?

YES >> GO TO 7.

NO >> Check harness and connectors based on the information obtained by interview. Refer to GI-42, "Intermittent Incident".

7.FINAL CHECK

With CONSULT-III

With CONSULT-III

1. Check the reference value for 4WD control unit.

2. Recheck the symptom and check that symptom is not reproduced on the same conditions.

Is the symptom reproduced? YES >> GO TO 3.

NO >> INSPECTION END

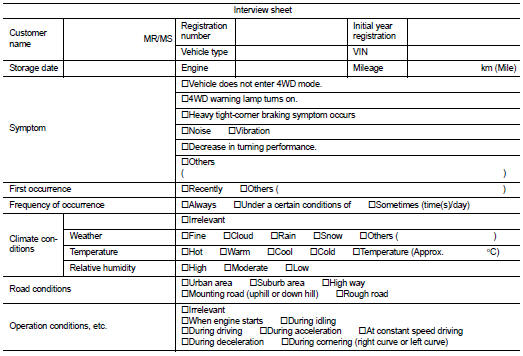

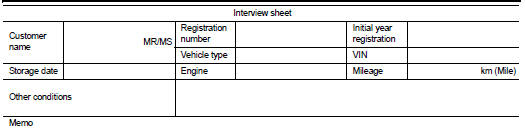

Diagnostic Work Sheet

Description

• In general, customers have their own criteria for a problem. Therefore, it is

important to understand the

symptom and status well enough by asking the customer about his/her concerns

carefully. To systemize all

the information for the diagnosis, prepare the interview sheet referring to the

interview points.

• In some cases, multiple conditions that appear simultaneously may cause a DTC to be detected.

Interview sheet sample

Basic inspection

Basic inspection

...

Writing unit parameter

Writing unit parameter

Description

Perform writing unit parameter of electric controlled coupling after

replacing 4WD control module, rear final

drive assembly or electric controlled coupling. Refer to DLN-39, "Wor ...

Other materials:

Power supply and ground circuit

A/C auto AMP. : Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom (A or B).

Which symptom is detected?

A >> GO TO 2.

B >> GO TO 5.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse (No. 3).

NOTE:

Refer to PG-23, "Fuse and Fusible Link Arrangement".

...

Door motor

Exploded View

LEFT SIDE

1. A/C unit assembly

2. Intake door lever

3. Intake door motor

4. Air mix door motor

5. Upper air mix door rod

6. Upper air mix door lever

7. Lower air mix door lever

8. Lower air mix door rod

RIGHT SIDE

1. A/C unit assembly

2. Main link

3. Sub defrost ...

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosis Description" (without Intelligent Key).

Does it operate normally?

YES >> INSPECTION ...