Nissan Juke Service and Repair Manual : Cooling fan

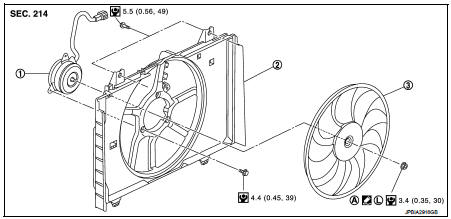

Exploded View

1. Fan motor

2. Fan shroud

3. Cooling fan

A. Apply on fan motor shaft

: Apply genuine high strength

: Apply genuine high strength

thread locking sealant or equivalent.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant from radiator. Refer to CO-37, "Draining".

CAUTION:

• Perform this step engine is cold.

• Never spill engine coolant on drive belt.

2. Remove air duct (inlet) and resonator assembly. Refer to EM-161, "Removal and Installation".

3. Remove reservoir tank as follows: a. Disconnect reservoir tank hose.

b. Release the tab (A) in the direction shown by the arrow (

).

).

c. Lift up and remove the reservoir tank with the tab released.

4. Remove radiator hose (upper). Refer to CO-42, "Exploded View".

5. Disconnect harness connector from fan motor, and move harness to aside.

6. Remove cooling fan assembly.

CAUTION:

Be careful not to damage or scratch on radiator core when removing.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Only use genuine parts for fan shroud mounting bolt and observe the specified

torque (to prevent

radiator from being damaged).

NOTE:

Cooling fan is controlled by ECM. For details, Refer to EC-774, "Component Function Check".

Disassembly and Assembly

DISASSEMBLY

1. Remove cooling fan mounting nut, and then remove the cooling fan.

2. Remove fan motor.

ASSEMBLY

Note the following, and assemble in the reverse order of disassembly.

• Apply genuine high strength thread locking sealant on fan motor shaft.

Inspection

Cooling Fan

Inspect cooling fan for crack or unusual bend.

• If anything is found, replace cooling fan.

Radiator

Radiator

Exploded View

1. Reservoir tank hose

2. Mounting rubber (upper)

3. Radiator tank cap

4. Radiator

5. Mounting rubber (lower)

6. O-ring

7. Drain plug

8. Clamp

9. Radiator hose (lower)

...

Water pump

Water pump

Exploded View

1. Gasket

2. Water pump

3. Water pump pulley

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Drain en ...

Other materials:

Checking engine oil level

1. Park the vehicle on a level surface and apply the parking brake.

2. Run the engine until it reaches operating temperature.

3. Turn off the engine. Wait more than 10 minutes for the oil to drain back into

the oil pan.

4. Remove the dipstick and wipe it clean.

Reinsert it all the way.

5. R ...

P1864 input speed signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...

Oil filter

Exploded View

1. O-ring

2. Oil filter bracket

3. Oil pressure switch

4. Oil filter

5. O-ring

6. Connecting bolt

A. To oil cooler

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Using an oil filter wrench [SST:KV113C0010 (Mot.1329) ...