Nissan Juke Service and Repair Manual : Cooler pipe and hose

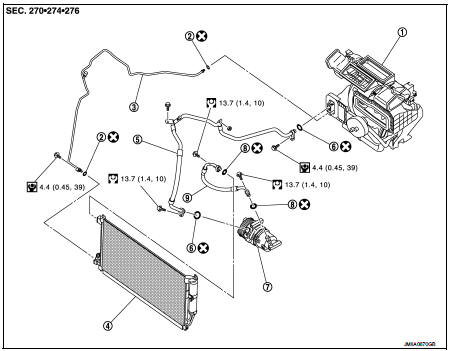

Exploded View

1. A/C unit assembly

2. O-ring

3. High-pressure pipe

4. Condenser

5. Low-pressure flexible hose

6. O-ring

7. Compressor

8. O-ring

9. High-pressure flexible hose

: Do not reuse

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

High-pressure flexible hose : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

23, "Perform Lubricant Return Operation

".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-21, "Recycle Refrigerant".

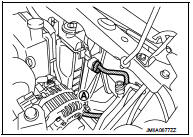

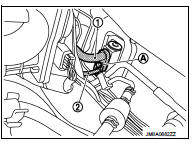

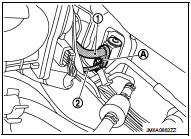

2. Remove mounting bolt (A), and then disconnect high-pressure flexible hose from condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with

suitable material such as vinyl tape to avoid the entry of air.

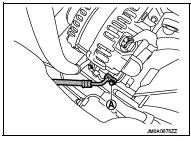

3. Remove mounting bolt (A), and then disconnect high-pressure flexible hose from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

4. Remove high-pressure flexible hose from vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-19, "Leak Test".

Low-pressure flexible hose : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

23, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-21, "Recycle Refrigerant".

2. Remove air duct. Refer to EM-161, "Removal and Installation".

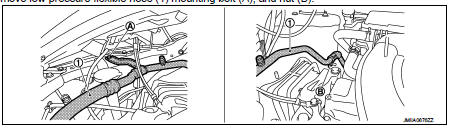

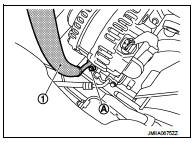

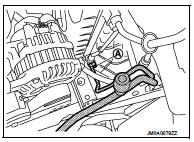

3. Remove low-pressure flexible hose (1) mounting bolt (A), and nut (B).

4. Remove plastic nut, and then move lower dash insulator aside.

: Plastic nut

: Plastic nut

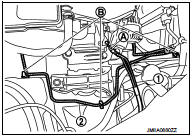

5. Remove mounting bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from expansion valve. Refer to HA-56, "EXPANSION VALVE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

6. Remove mounting bolt (A), and then remove low-pressure flexible hose (1) from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-19, "Leak Test".

High-pressure pipe : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

23, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-21, "Recycle Refrigerant".

2. Remove air duct. Refer to EM-161, "Removal and Installation".

3. Remove low-pressure flexible hose (1) mounting bolt (A), and nut (B).

4. Remove plastic nut, and then move lower dash insulator aside.

: Plastic nut

: Plastic nut

5. Remove mounting bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from expansion valve. Refer to HA-56, "EXPANSION VALVE : Removal and Installation".

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

6. Remove mounting bolt (A), and then disconnect high-pressure pipe from condenser.

CAUTION:

Cap or wrap the joint of the A/C piping and condenser with

suitable material such as vinyl tape to avoid the entry of air.

7. Remove mounting bolt (A), and then remove ground wire (1) from engine unit.

8. Remove high-pressure pipe (2) fixing clips (B), and then remove high-pressure pipe.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Check for leakages when recharging refrigerant. Refer to HA-19, "Leak Test".

Compressor

Compressor

Exploded View

REMOVAL

1. High-pressure flexible hose

2. O-ring

3. Compressor

4. O-ring

5. Low-pressure flexible hose

A. To condenser

B. To evaporator

: N·m (kg-m, ft-lb)

DISASSEMBLY

...

Condenser

Condenser

Exploded View

1. Condenser

2. Refrigerant pressure sensor

3. O-ring

4. Grommet

5. Braket

6. O-ring

7. Liquid tank braket

8. Liquid tank

: Do not reuse

: N·m (kg-m, in-lb)

: N·m (kg-m ...

Other materials:

Rear-facing child restraint installation using the seat belts

WARNING

The three-point seat belt with Automatic Locking Retractor (ALR) must be used

when installing a child restraint.

Failure to use the ALR mode will result in the child restraint not being properly

secured. The restraint could tip over or be loose and cause injury to a child in

a sudd ...

C1109 power and ground system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

B1184 lap Pre-tensioner LH

DTC Logic

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC ...