Nissan Juke Service and Repair Manual : Compressor

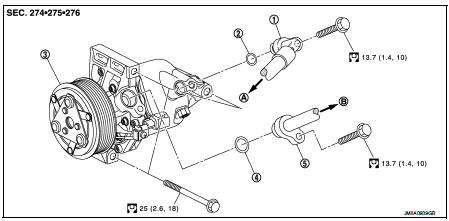

Exploded View

REMOVAL

1. High-pressure flexible hose

2. O-ring

3. Compressor

4. O-ring

5. Low-pressure flexible hose

A. To condenser

B. To evaporator

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

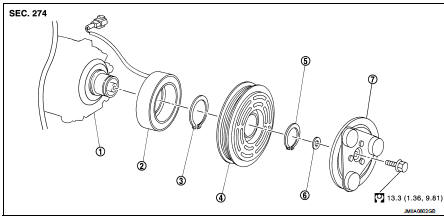

DISASSEMBLY

1. Compressor unit

2. Field coil

3. Snap ring

4. Pulley assembly

5. Snap ring

6. Shim

7. Clutch disc

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Compressor : Removal and Installation

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly.

However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return

operation. Refer to HA-

78, "Perform Lubricant Return Operation".

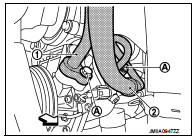

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to HA-76, "Recycle Refrigerant".

2. Remove drive belt. Refer to EM-20, "Removal and Installation".

3. Remove mounting bolts (A), and then disconnect low-pressure flexible hose (1) and high-pressure flexible hose (2). (compressor side)

: Vehicle front

: Vehicle front

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

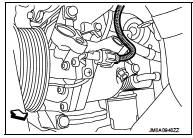

4. Disconnect magnet clutch harness connector.

: Vehicle front

: Vehicle front

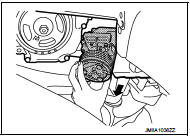

5. Remove mounting bolts. Pull out compressor in the direction indicated by an arrow as shown in the figure to remove.

CAUTION:

Be careful not to contact with and damage surrounding

parts when removing compressor from the vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when

installing.

• Perform lubricant adjusting procedure before installing new compressor. Refer to HA-79, "Lubricant Adjusting Procedure for Compressor Replacement".

• Check for leakages when recharging refrigerant. Refer to HA-74, "Leak Test".

• Check tension of the drive belt after installing compressor. Refer to EM-20, "Checking".

Magnet clutch : Removal and Installation of Compressor Clutch

REMOVAL

Overhaul

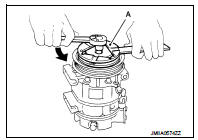

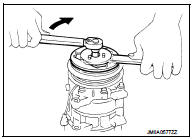

1. When removing center bolt, hold clutch disc with clutch disc

wrench (SST:KV99232340) (A).

2. Remove clutch disc.

3. Remove snap ring using external snap ring pliers.

4. Position center pulley puller on the end of the drive shaft, and remove pulley assembly using any commercially available pulley puller.

To prevent pulley groove from being deformed, puller claws should be positioned into the edge of the pulley assembly.

5. Disconnect harness connector from compressor unit.

6. Remove snap ring using external snap ring pliers, and then remove field coil.

INSTALLATION

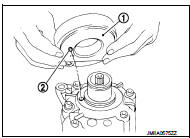

1. Install field coil (1).

Be sure to align the coil’s pin (2) with the hole in the compressor’s front head.

2. Install field coil harness clip.

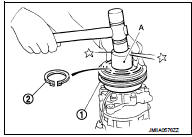

3. Install pulley assembly (1) using pulley installer (SST:KV99106200) (A) and a hand press, and then install snap ring (2) using snap ring pliers.

4. Install clutch disc on drive shaft, together with original shim(s). Press clutch disc down by hand.

5. Tighten center bolt to the specified torque while fixing clutch disc not to rotate using a clutch disc wrench (SST:KV99232340).

After tightening the bolt, check that the pulley rotates smoothly.

Break-in Operation

When replacing compressor clutch assembly, always perform the break-in

operation, by engaging and disengaging

the clutch approximately 30-times. Break-in operation increases the level of

transmitted torque.

Inspection

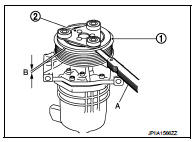

CHECK DISC TO PULLEY CLEARANCE

Check the clearance (B) between pulley assembly (1) and clutch disc (2) along the entire periphery with a feeler gauge (A).

Clearance : Refer to HA-118, "Compressor".

Replace compressor if specified clearance is not obtained.

Cooler pipe and hose

Cooler pipe and hose

Exploded View

1. A/C unit assembly

2. O-ring

3. High-pressure pipe

4. O-ring

5. Low-pressure flexible hose

6. High-pressure flexible hose

7. O-ring

8. Condenser

9. Compressor

: Do not ...

Other materials:

Daytime running light relay circuit

Component Function Check

1.CHECK DAYTIME RUNNING LIGHT OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test item, check that parking lamp, tail lamp and license

plate lamp are turned ON.

TAIL : Parking lamp, tail lamp and licens ...

Outside key antenna

Driver side

DRIVER SIDE : Removal and Installation

REMOVAL

Remove the driver side outside handle. Refer to DLK-176, "OUTSIDE HANDLE :

Removal and Installation".

INSTALLATION

Install in the reverse order of removal.

Passenger side

PASSENGER SIDE : Removal and Installation

REMOVA ...

A/C indicator

Diagnosis Procedure

1.CHECK SYMPTOM

Check symptom.

A/C indicator dose not turn ON>>GO TO 2.

A/C indicator dose not turn OFF>>GO TO 6.

2.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 10A fuse (No. 15, located in fuse block (J/B)].

NOTE:

Refer to PG-22, "Fuse, Conn ...