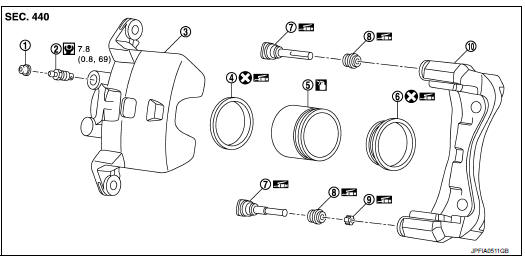

Nissan Juke Service and Repair Manual : Components

• THE LARGE ILLUSTRATIONS

are exploded views (see the following) and contain tightening torques, lubrication points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information necessary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the appropriate PARTS CATALOG.

Components shown in an illustration may be identified by a circled number. When this style of illustration is used, the text description of the components will follow the illustration.

1. Cap

2. Bleeder valve

3. Cylinder body

4. Piston seal

5. Piston

6. Piston boot

7. Sliding pin

8. Sliding pin boot

9. Bushing

10. Torque member

: Apply rubber grease.

: Apply rubber grease.

: Apply brake fluid.

: Apply brake fluid.

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly

SYMBOLS

Relation between Illustrations and Descriptions

Relation between Illustrations and Descriptions

The following sample explains the relationship between the part description

in an illustration, the part name in

the text and the service procedures.

...

Other materials:

P2119 electric throttle control function

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1. Replace electric t ...

System

System Diagram

System Description

REFRIGERANT CYCLE

Refrigerant Flow

The refrigerant from the compressor, flows the condenser with liquid tank, the

evaporator, and returns to the

compressor. The refrigerant evaporation in the evaporator is controlled by an

expansion valve.

Freeze Prote ...

Transmission range switch

Exploded View

1. Transmission range switch

2. Transaxle assem

Removal and Installation

REMOVAL

1. Remove battery. Refer to PG-124, "Removal and Installation".

2. Remove transmission range switch connector.

3. Remove control cable. Refer to TM-273, "Removal and Installation&q ...