Nissan Juke Service and Repair Manual : Component parts

Component Parts Location

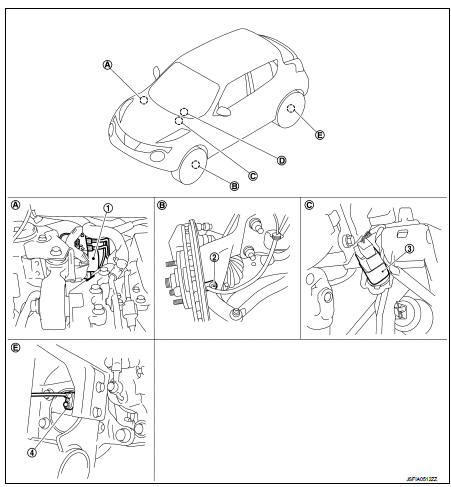

LHD

1. ABS actuator and electric unit (control

unit)

2. Front wheel sensor

3. Stop lamp switch

4. Rear wheel sensor

A. Inside engine room

B. Steering knuckle

C. Brake pedal

D. ABS warning lamp, brake warning

lamp (in combination meter)

E. Rear wheel hub and bearing assembly

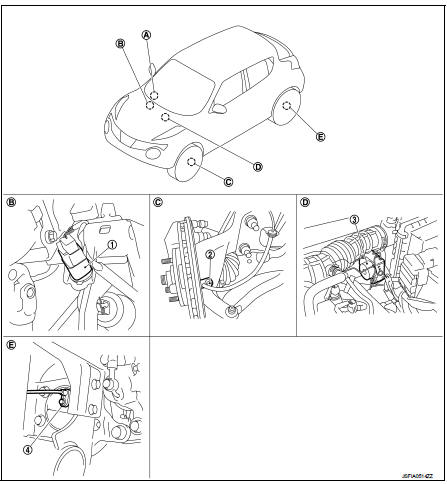

RHD

1. Stop lamp switch

2. Front wheel sensor

3. ABS actuator and electric unit (control

unit)

4. Rear wheel sensor

A. ABS warning lamp, brake warning

lamp (in combination meter)

B. Brake pedal

C. Steering knuckle

D. Inside engine room

E. Rear wheel hub and bearing assembly

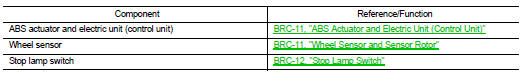

Component Description

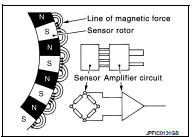

Wheel Sensor and Sensor Rotor

NOTE

:

• Wheel sensor of front wheel is installed on steering knuckle.

• Sensor rotor of front wheel is integrated in wheel hub and bearing assembly.

• Wheel sensor of rear wheel is installed on wheel hub and bearing assembly.

• Sensor rotor of rear wheel is integrated in wheel hub and bearing assembly.

• Never measure resistance and voltage value using a tester because sensor is active sensor.

• Downsize and weight reduction is aimed. IC for detection portion and magnet for sensor rotor are adopted.

• Power supply is supplied to detection portion so that magnetic field line is read. Magnetic field that is detected is converted to current signal.

• When sensor rotor rotates, magnetic field changes. Magnetic field change is converted to current signals (rectangular wave) and is transmitted to ABS actuator and electric unit (control unit). Change of magnetic field is proportional to wheel speed.

ABS Actuator and Electric Unit (Control Unit)

Electric unit (control unit) is integrated with actuator and comprehensively controls ABS function and EBD function.

ELECTRIC UNIT (CONTROL UNIT)

• Brake fluid pressure are controlled according to signals from each sensor.

• If malfunction is detected, the system enters fail-safe mode.

ACTUATOR

The following components are integrated with ABS actuator.

Pump

Returns the brake fluid reserved in reservoir to master cylinder by reducing

pressure.

Motor

Activates the pump according to signals from ABS actuator and electric unit

(control unit).

Motor Relay

Operates the motor ON/OFF according to signals from ABS actuator and electric

unit (control unit).

Actuator Relay (Main Relay) Operates each valve ON/OFF according to signals from ABS actuator and electric unit (control unit).

ABS IN Valve

Switches the fluid pressure line to increase or hold according to signals from

control unit.

NOTE

:

Valve is a solenoid valve.

ABS OUT Valve

Switches the fluid pressure line to increase, hold or decrease according to

signals from control unit.

NOTE

:

Valve is a solenoid valve.

Inlet Valve

Brake fluid sucked from the reservoir by the pump does not backflow.

NOTE

:

Valve is a check valve.

Outlet Valve

Brake fluid discharged from the pump does not backflow.

NOTE

:

Valve is a check valve.

Return Check Valve

Returns the brake fluid from brake caliper to master cylinder by bypassing

orifice of each valve when brake is

released.

Reservoir

Temporarily reserves the brake fluid drained from brake caliper, so that

pressure efficiently decreases when

decreasing pressure of brake caliper.

Stop Lamp Switch

Detects the operation status of brake pedal and transmits converted electric signal to ABS actuator and electric unit (control unit).

System

System

System Description

• The system switches fluid pressure of each brake caliper to increase, to

hold or to decrease according to

signals from control unit in ABS actuator and electric unit (control ...

Other materials:

P1642 thermoplunger control unit

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK THERMOPLUNGER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect thermoplunger control unit harness connector.

3. Check the voltage between thermoplunger control unit harness connector and

ground.

Is the ...

Magnet clutch

Component Function Check

1.CHECK MAGNET CLUTCH OPERATION

Perform auto active test of IPDM E/R. Refer to PCS-12, "Diagnosis

Description" (with Intelligent Key) or PCS-

43, "Diagnosis Description" (without Intelligent Key).

Does it operate normally?

YES >> INSPECTION ...

Service Notice or Precautions for Clut

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Never use compressed

air.

CAUTION:

• Clutch fluid use refer to MA-13, "Fluids and Lubricants".

• Never reuse drained clutch fluid.

• Keep painted surface on the body or other parts free of clutch fluid. If it

sp ...