Nissan Juke Service and Repair Manual : Clutch piping

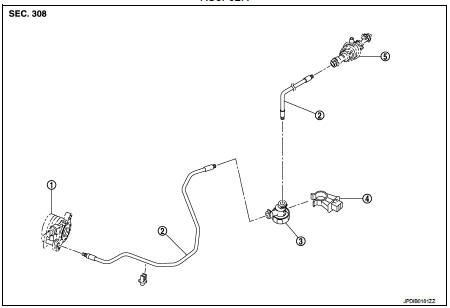

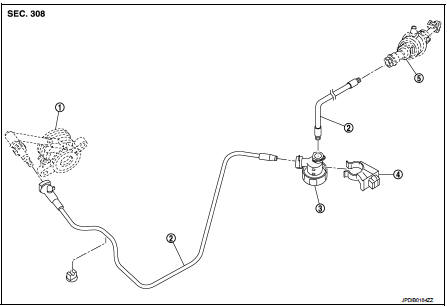

Exploded View

RS5F92R

1. CSC (Concentric Slave Cylinder)

2. Clutch tube

3. Clutch damper

4. Bracket

5. Master cylinder

RS6F94R

1. CSC (Concentric Slave Cylinder)

2. Clutch tube

3. Clutch damper

4. Bracket

5. Master cylinder

Hydraulic Layout

1. Clutch tube

2. Lock pin

3. CSC (Concentric Slave Cylinder)

4. Clutch damper

5. Master cylinder

6. Clutch pedal

Removal and Installation

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

REMOVAL

Note the following, and refer to CL-24, "Exploded View" for removal procedure.

• Drain clutch fluid. Refer to CL-10, "RS5F92R : Draining" (RS5F92R) or CL-13, "RS6F94R : Draining" (RS6F94R).

• Press the lock pin into the bleeding connector of the CSC, and then remove clutch tube from CSC.

• Pull the lock pins from the connectors of the clutch damper until the pins stop, and then remove clutch tubes from clutch damper.

• Pull the lock pin from the connector of the clutch master cylinder until the pin stop, and then remove clutch tube from clutch master cylinder.

INSTALLATION

Note the following, and refer to CL-24, "Exploded View" for installation procedure.

CAUTION:

Never damage clutch tube.

• Insert each clutch tube into the CSC bleeding connector, the clutch damper connector, and the clutch master cylinder connector until it contacts the end of each connector.

• Install each lock pin into the clutch damper connector and the clutch master cylinder connector until it contacts the end of each connector.

Inspection and Adjustment

INSPECTION AFTER REMOVAL

• Check the clutch tube for cracks and damage. If the clutch tube has cracks or damage, replace it with a new one.

• Check the O-ring of the clutch tube for cracks and damage. If the O-ring of the clutch tube has cracks or damage, replace clutch tube with a new one.

• Check the clutch damper for cracks and damage. If the clutch damper has cracks or damage, replace it with a new one.

INSPECTION AFTER INSTALLATION

• Check the fluid leakage and the fluid level. Refer to CL-10, "RS5F92R : Inspection" (RS5F92R) or CL-13, "RS6F94R : Inspection" (RS6F94R).

• Check the clutch pedal height, clutch pedal height at clutch disengagement, and clutch pedal play. Refer to CL-7, "Inspection and Adjustment".

ADJUSTMENT AFTER INSTALLATION

Perform the air bleeding. Refer to CL-12, "RS5F92R : Air Bleeding" (RS5F92R) or CL-15, "RS6F94R : Air Bleeding" (RS6F94R).

Clutch master cylinder

Clutch master cylinder

LHD : Exploded View

1. Reservoir hose

2. Reservoir tank

3. Master cylinder

LHD : Removal and Installation

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch f ...

Other materials:

B1066, B1071 passenger air bag module

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

P0110 IAT sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

Fuel injector and fuel tube

Exploded View

1. Stud bolt

2. O-ring (green)

3. Fuel injector (front)

4. Clip

5. Fuel injector (rear)

6. O-ring (black)

7. Fuel tube protector

8. Fuel tube

9. Fuel feed hose

10. Quick connector cap

A. To centralized under-floor piping

: Always replace after every

disassembly.

...