Nissan Juke Service and Repair Manual : Brake pedal

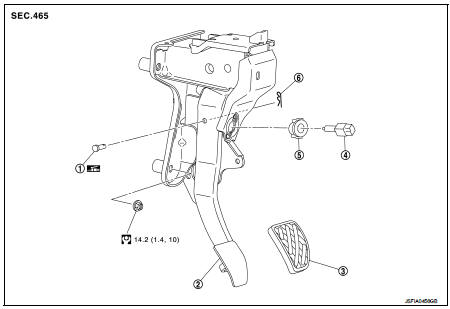

Exploded View

WITHOUT ESP

1. Clevis pin

2. Brake pedal assembly

3. Brake pedal pad

4. Stop lamp switch

5. Clip

6. Snap pin

: Apply multi-purpose grease.

: Apply multi-purpose grease.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

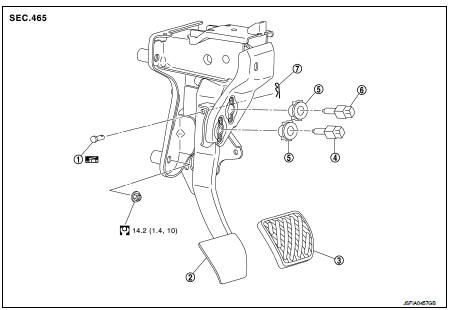

WITH ESP

1. Clevis pin

2. Brake pedal assembly

3. Brake pedal pad

4. Brake switch/brake pedal position

switch

5. Clip

6. Stop lamp switch

7. Snap pin

: Apply multi-purpose grease.

: Apply multi-purpose grease.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Remove instrument lower panel. Refer to IP-13, "Removal and Installation".

2. Disconnect the stop lamp switch and the brake switch/brake pedal position switch harness connectors.

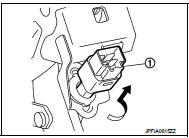

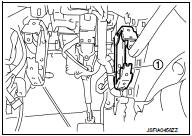

3. Rotate the stop lamp switch and the brake switch/brake pedal position switch (1) counter clockwise to remove.

4. Disconnect the accelerator pedal harness connector and harness clip.

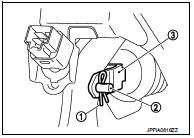

5. Remove snap pin (1) and clevis pin (2) from clevis (3) of brake booster.

6. Remove the steering member stay (1).

7. Remove the brake pedal assembly.

CAUTION:

Hold the brake booster and master cylinder assembly so as

not to drop out or contact them other parts.

8. Remove accelerator pedal from brake pedal assembly. Refer to ACC-3, "Removal and Installation".

9. Perform inspection after removal. Refer to BR-22, "Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

• Apply the multi-purpose grease to the clevis pin and the mating faces. (Not necessary if grease has been already applied) NOTE

:

The clevis pin may be inserted in either direction.

• Perform adjustment after installation. Refer to BR-22, "Inspection and Adjustment".

Inspection and Adjustment

INSPECTION AFTER REMOVAL

• Check for the following items and replace the brake pedal assembly if necessary.

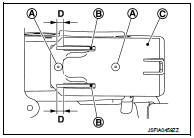

- Check the brake pedal upper rivet (made by aluminum) (A) for deformation.

- Check the brake pedal for bend, damage, and cracks on the welded parts.

- Check the lapping length (D) of sub-bracket (B) and slide plate (C).

D : 6.5 mm (0.256 in) or more

• Check clevis pin and plastic stopper (A) for damage and deformation.

If any is found, replace clevis pin.

ADJUSTMENT AFTER INSTALLATION

• Adjust each item of brake pedal after installing the brake pedal assembly to the vehicle. Refer to BR-9, "Inspection and Adjustment".

• Perform the release position learning of the accelerator pedal.

- MR16DDT: Refer to EC-134, "Work Procedure".

- HR16DE: Refer to EC-542, "Work Procedure".

Brake piping

Brake piping

Front : Exploded View

WITHOUT ESP

1. Brake tube

2. ABS actuator and electric unit (control

unit)

3. Connector

4. Connector bracket

5. Master cylinder assembly

6. Brake booster

7. Lock pl ...

Other materials:

Drinking alcohol/drugs and driving

WARNING

Never drive under the influence of alcohol or drugs. Alcohol in the bloodstream

reduces coordination, delays reaction time and impairs judgement.

Driving after drinking alcohol increases the likelihood of being involved in

an accident injuring yourself and others.

Additionally, if you ...

P2127, P2128 APP sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following proced ...

P0544 EGT sensor 1

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...