Nissan Juke Service and Repair Manual : B2601 shift position

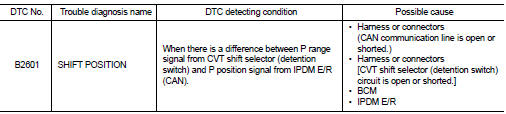

DTC Logic

DTC DETECTION LOGIC

NOTE

:

• If DTC B2601 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2601 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to BCS-84, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Shift the selector lever to the P position.

2. Turn ignition switch ON and wait 2 seconds or more.

3. Shift the selector lever to any position other than P, and wait 2 seconds or more.

4. Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected? YES >> Go to SEC-79, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

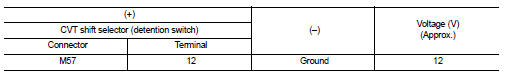

1.CHECK CVT SHIFT SELECTOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect CVT shift selector (detention switch) connector.

3. Check voltage between CVT shift selector (detention switch) harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

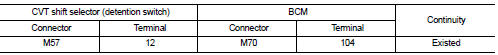

2.CHECK CVT SHIFT SELECTOR POWER SUPPLY CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between CVT shift selector (detention switch) harness connector and BCM harness connector.

3. Check continuity between CVT shift selector (detention switch) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.REPLACE BCM

1. Replace BCM. Refer to BCS-93, "Removal and Installation".

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT-III.

For initialization and registration procedures, refer to CONSULT-III Operation Manual NATS-IVIS/NVIS.

>> INSPECTION END

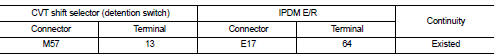

4.CHECK CVT SHIFT SELECTOR CIRCUIT (IPDM E/R)

1. Disconnect IPDM E/R connector.

2. Check continuity between CVT shift selector (detention switch) harness connector and IPDM E/R harness connector.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace harness.

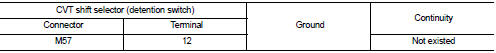

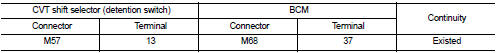

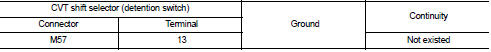

5.CHECK CVT SHIFT SELECTOR CIRCUIT (BCM)

1. Disconnect BCM connector.

2. Check continuity between CVT shift selector (detention switch) harness connector and BCM harness connector.

3. Check continuity between CVT shift selector (detention switch) harness connector and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace harness.

6.REPLACE BCM

1. Replace BCM. Refer to BCS-93, "Removal and Installation".

2. Perform initialization of BCM and registration of all Intelligent Keys using CONSULT-III.

For initialization and registration procedures, refer to CONSULT-III Operation Manual NATS-IVIS/NVIS.

3. Perform DTC CONFIRMATION PROCEDURE for DTC B2601. Refer to SEC-79, "DTC Logic".

Is DTC B2601 detected again? YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation".

NO >> INSPECTION END

B2557 vehicle speed

B2557 vehicle speed

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2557 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2557 is disp ...

B2602 shift position

B2602 shift position

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B2602 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

BCS-83, "DTC Logic".

• If DTC B2602 is disp ...

Other materials:

Steering wheel turning force is heavy or light

Description

Steering wheel turning force is heavy or light.

Diagnosis Procedure

1.CHECK THE ILLUMINATION OF THE EPS WARNING LAMP

Check that the EPS warning lamp turns ON when ignition switch turns ON. Then,

EPS warning lamp turns

OFF after the engine is started.

Is the inspection result no ...

Side oil seal

Exploded View

1. Rear final drive assembly

2. Side oil seal (right)

3. Electric controlled coupling (right)

4. Reamer bolt

5. Side oil seal (left)

6. Electric controlled coupling (left)

A. Oil seal lip B. Gear carrier mouting face

: Vehicle front

: N·m (kg-m, ft-lb)

: Always replace ...

Inspection

OIL LEAKAGE

Check transfer surrounding area (oil seal, drain plug, filler plug, and

transfer case etc.) for oil leakage.

OIL LEVEL

1. Remove filler plug (1) and gasket. Then check that oil is filled up

from mounting hole for the filler plug.

Vehicle front

CAUTION:

Never start engine while ...